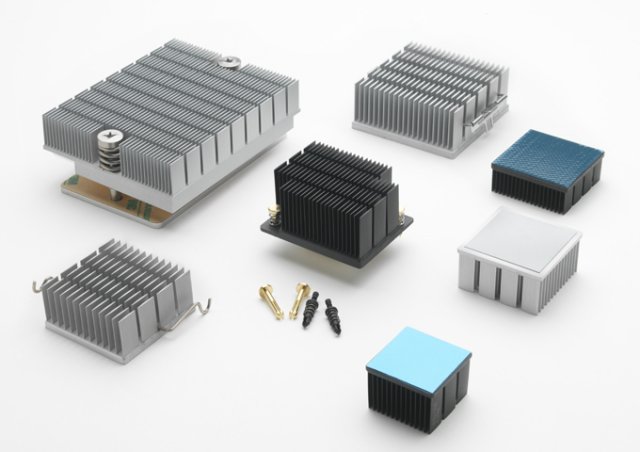

There are several approaches to improving the thermal performance of a heat sink. In this section, we introduce the methods that Alpha typically recommends. However, the optimal approach will vary significantly, depending on the actual operating variables (such as available space, airflow conditions, etc.). The effectiveness and cost/performance of each method will differ from case to case.

If you require optimization or evaluation based on specific design conditions, please contact Alpha sales for details. We will propose the most suitable thermal solution for your application.

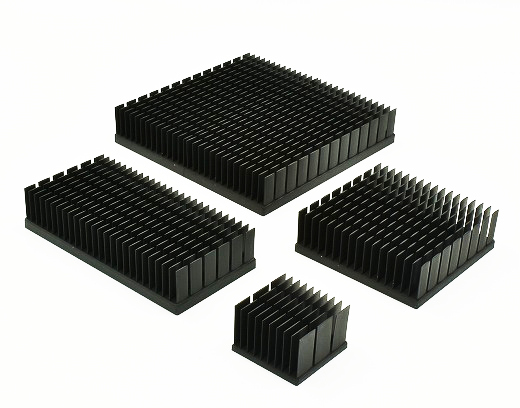

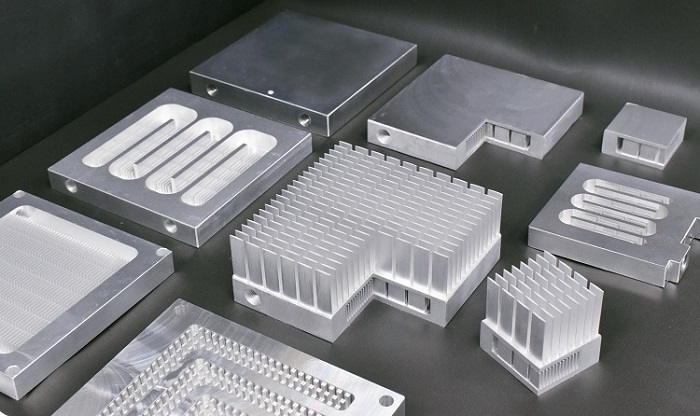

Using a larger base size to increase the surface area is a simple and effective method to improve thermal performance. Alpha offers a wide range of standard heat sink sizes (click here for Quick Reference by Heat Sink Base Size), making it easy to find a suitable model for your application. If you cannot find the right size, we can customize the heat sink dimensions at minimal additional cost. We can also manufacture heat sinks larger than the standard sizes using FSW technology.

Increasing heat sink height is also a simple and effective way to improve the thermal performance. Each standard heat sink page has multiple height options (Example, LPD70 heatsink page), making it simple to select the ideal height for your application. Also, we are very flexible with regards to fin length and base thickness, and can create a semi-custom version at minimal additional cost. In some cases, using multiple heights/steps (Example) can also be an effective way to maximize surface area.

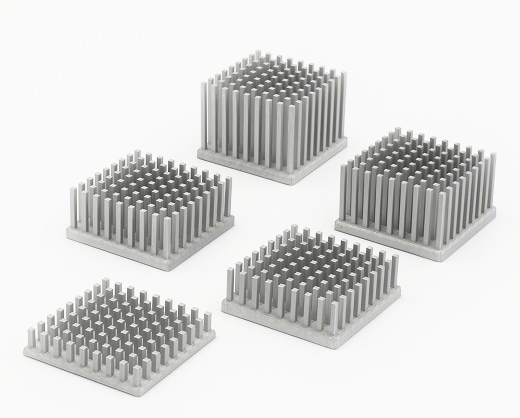

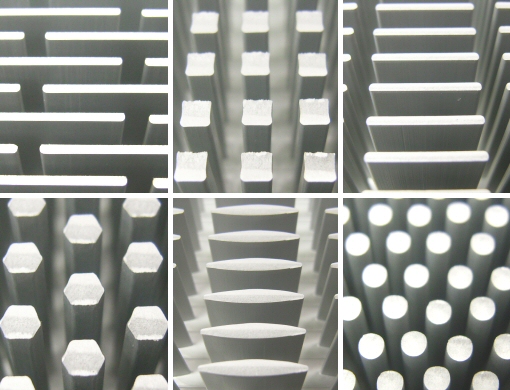

Optimizing the fin pattern for the application is one of the most effective ways to improve thermal performance. Under forced-air convection, denser fin patterns offer greater surface area and improved thermal performance. However, under low or no airflow conditions, a sparse fin pattern—such as the N series or LPD series will often perform better due to the reduced pressure drop. Our website features a Thermal Simulation Tool that helps customers determine the most suitable fin pattern based on environmental conditions. Aligning the fin direction to airflow and/or gravity is also important under both forced and natural convection conditions.

Fin density under natural convection

Heat sink orientation and thermal performance under natural convection

Using a fan(s) with a higher airflow and/or higher static pressure can significantly improve heat sink performance.

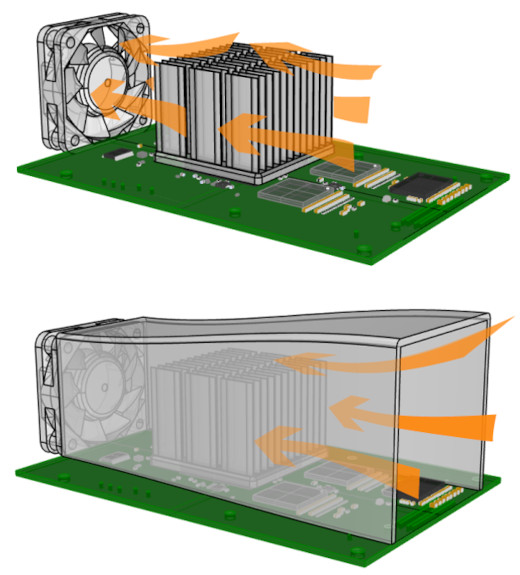

Airflow bypass around the heat sink significantly degrades performance. When there are large open areas around the heat sink, a substantial portion of the cooling air flows around the fins instead of through them. As discussed in the #1 (Use a larger base size) and #2 (Use taller Heat Sink) sections, increasing heat sink size not only increases surface area but also reduces the bypass area, improving airflow through the fins and the performance of the heat sink.

Top : Non-ducted image

Bottom : Ducted image

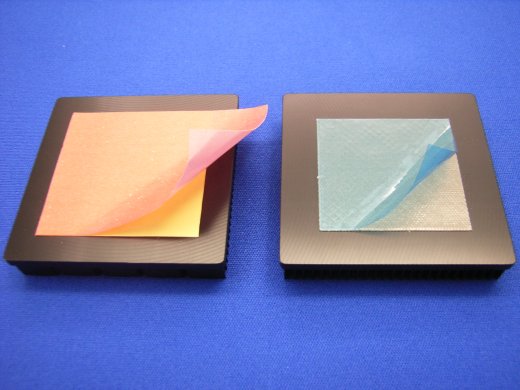

TIM (Thermal Interface Material) plays a critical role in thermal performance. Upgrading to a higher-performance TIM is especially effective when the contact area between the heat source and heat sink is small and/or when power dissipation is high. Also, using the correct TIM type for the application is crucial. For example, a thick compliant gap pad material would be required when a single heat sink is cooling multiple devices. Please see here for details. Alpha offers a variety of standard TIM options, enabling customers to easily select the material that best fits their needs.

Most TIMs are pressure-sensitive, and increasing mounting pressure will improve thermal performance. Alpha offers several standard heat sink attachment options standard heatsink standard heatsink attachment option (Z-shape clip, pushpin, shoulder screw, etc) enabling us to easily adjust heat sink attachment force/pressure to meet customer requirements. Please note that excessive mounting force/pressure may cause issues such as chip damage or PCB warping. Care must be taken when selecting the mounting option and final hardware components.

A fan can be mounted directly on the heat sink to create an active heat sink assembly. This is a very effective method to improve performance in environments where sufficient airflow is not available. Alpha offers several standard fan options and fan/heat sink combinations. If required, we can also create a custom active heat sink solution.

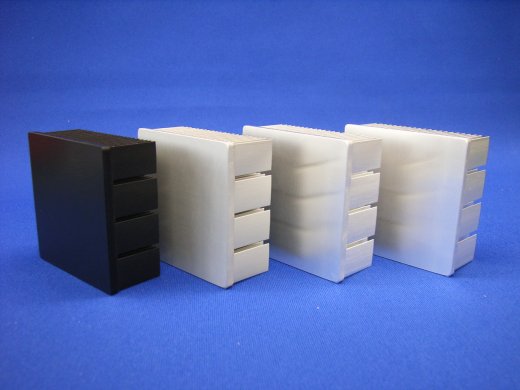

Surface finish will impact emissivity and therefore influence dissipation through thermal radiation. We recommend an anodized finish for natural convection applications with no airflow. Anodized aluminum has a higher emissivity than bare aluminum. Under natural convection conditions, the contribution of radiative heat transfer is far more significant than it is in forced convection conditions where significant airflow is present. Our natural convection heat sinks (LPD series, N series) are provided with an anodized finish.

(Image from left) Black anodize, clear anodize, trivalent chromate, no surface finish

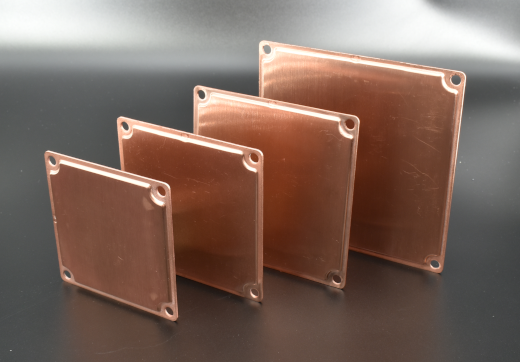

To significantly improve thermal performance, we embed a copper heat spreader into the aluminum heat sink base. Copper's superior thermal conductivity reduces spreading resistance, making this solution especially effective when the heat source contact area is small relative to the heat sink base size. Alpha offers several standard copper-embedded heat sinks, such as the UBC series and LC series. However, almost any heat sink can be embedded with a copper spreader to improve performance.

Left : All aluminum Heat Sink (black anodized)

Right : Aluminum Heat Sink with a copper embedded base

* The copper embedded surface cannot be anodized.

A vapor chamber can be integrated into the heat sink base to significantly improve heat spreading. This is highly effective when the heat source area is small compared with the heat sink base size. Alpha offers several standard vapor chambers, and they can be assembled with many of our standard heat sinks. When attaching a vapor chamber to a heat sink, we use a thermal interface material and fasteners, or a high conductivity thermal adhesive.

Alpha offers high-performance cold plates for customers requiring liquid-cooling solutions. By incorporating internal micro-fins, we significantly increase the surface area in contact with the coolant, maximizing heat exchange efficiency. This ensures stable, reliable cooling for high-power devices that cannot be effectively managed with traditional air cooling.