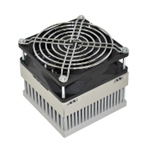

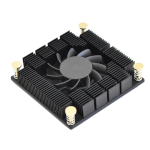

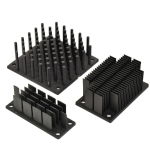

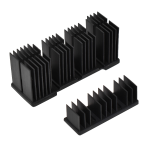

Heat Sink

Accessories

Additional Information

Introduction

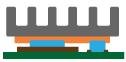

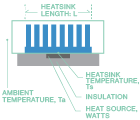

Design

Guidelines and

Considerations

Guidelines and

Considerations

Additional

Design Tools

and Information

Design Tools

and Information

Data

Inquiries | © 2025 Alpha Company Ltd.